Reinventing laser measuring technology with the new LC50-DIGILOG!

Fast. Precise. Reliable.

- Highly dynamic measurement of all tool parameters

- Up to 60% less measuring and checking time

- Absolute accuracy, better than all comparable measuring systems

- High-end laser optics for optimum performance under the harshest conditions

- Low-manpower, automated operation

Introducing: LC50-DIGILOG

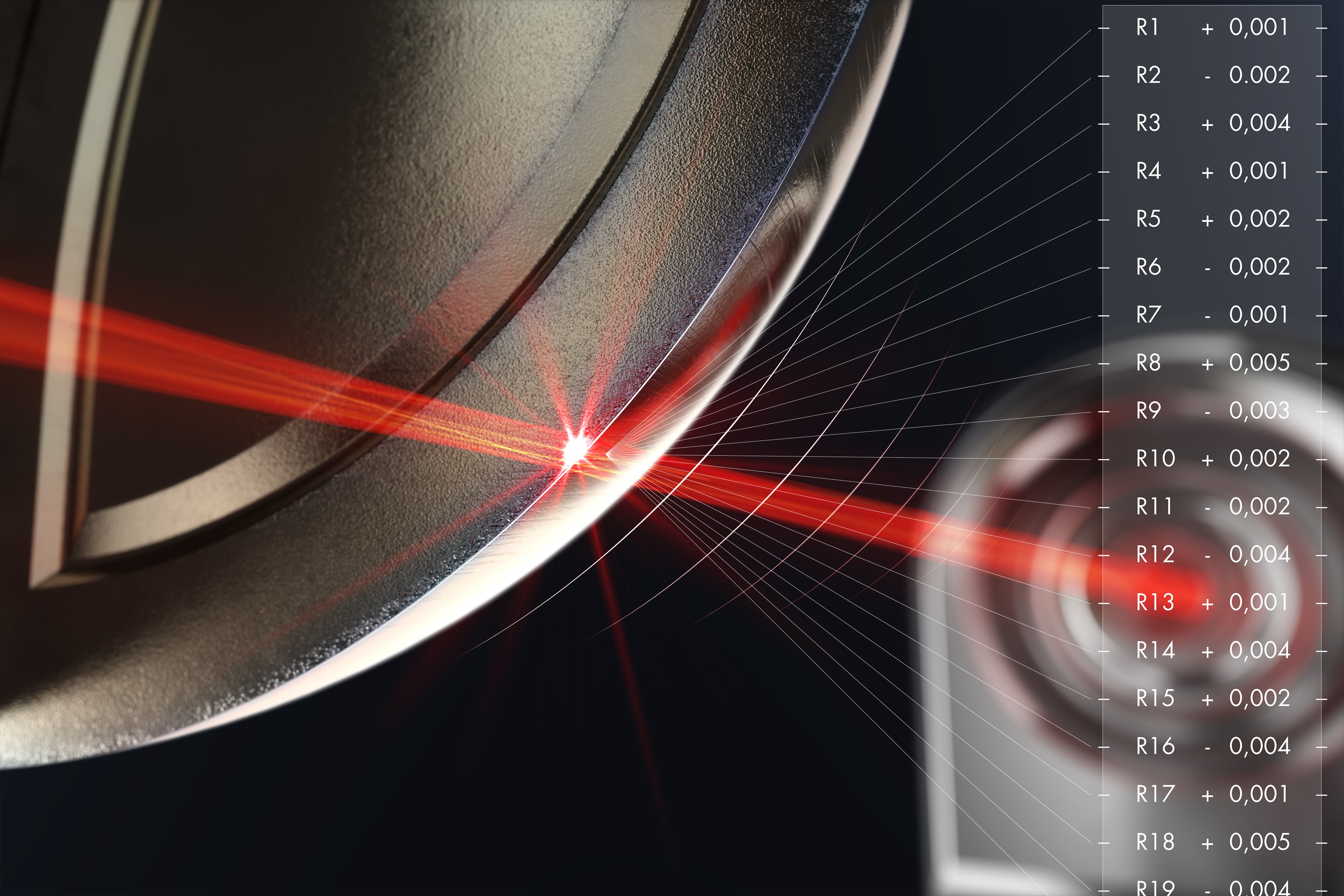

The new laser measuring system LC50-DIGILOG is a ground-breaking system that has been completely redeveloped to revolutionize and future-proof the speed, precision and in-process reliability of tool measurement in machines tools thanks to the latest possible applications. The hardware also features lots of brilliant technical innovations.

Alexander Blum, President of Blum-Novotest GmbH, says: “In-machine measurement has become established as an integral element of high-end CNC machining. Automated machines and virtually all five-axis machining centers are nowadays equipped with BLUM laser measuring systems. The prerequisite for this was the outstanding performance of systems under the harshest conditions as well as the associated possibilities in terms of automated tool measurement and monitoring. Based on that, it was by no means easy to upgrade the tried and proven laser measuring technology with NT technology. We achieved this innovative advancement by implementing the DIGILOG technology familiar from touch probes in the laser measuring system.”

BLUM laser measuring systems have always been renowned for their high precision and in-process reliability. Thanks to the newly implemented DIGILOG technology, those attributes have been enhanced to a never before imagined level. Whereas the proven digital/switching laser measuring systems using NT technology only generate a small number of signals for recording measurements by shadowing the tool, the new DIGILOG laser measuring systems generate many thousands of measurement values per second while dynamically adjusting the measuring speed according to the nominal speed of the tool. The new laser measuring system LC50-DIGILOG also measures each cutting edge individually, rather than just determining the value for the longest cutting edge, meaning it is possible to make a comparison from the shortest to the longest cutting edge. As a result, run-out errors, caused by contamination on the taper of the tool holder for example, are also automatically detected. Furthermore, the new LC50-DIGILOG detects any contaminants and cooling lubricants adhering to the tool – due to the large number of measurements per cutting edge – and deducts them from the result to make measurement results even more reliable.

The many new ideas implemented by the BLUM developers in the LC50-DIGILOG have resulted in impressive advantages for users: Firstly, measurement and testing times have been shortened by up to 60 percent. In addition, the optics in the system were further improved so that the new generation achieves an absolute accuracy that is better than all comparable measuring systems thanks to an optimized beam shape and a 30 percent smaller focus diameter. BLUM's developers have also further improved the homogeneity of the laser beam, making further analogue measurements possible. The influence of coolant mist has been further reduced enabling improvements in accuracy and in-process reliability. And despite its reduced external dimensions, the optimized design enables the measurement of tools that are up to 30 percent bigger, depending on the version used.

The compact BLUM smartDock represents another world-first. This innovative standard interface serves as the basis for all new support systems and contains all the necessary pneumatic valves in addition to the electrical, mechanical and pneumatic connections between the machine and laser measuring system. If the compressed air quality is in accordance with ISO 8573-1 class 1.3.1, the separate pneumatic unit required for the LaserControl NT can even be omitted completely.

“With the LC50-DIGILOG laser measuring system, we have succeeded in raising a tried and proven technology to a new level. In addition to realizing the shortest measurement times, optimized precision and in-process reliability, users will also profit in the future from new, ground-breaking applications. These include the 3D ToolControl software, which enables continuous DIGILOG-based contour measurement of tools – including the visualization on the control screen – which far exceeds the functions of significantly more expensive and complex image-processing systems. Or the new ‘SpindleControl’ technology cycle, which can be used to record and evaluate the state of a spindle bearing“, sums up Alexander Blum.

Want to learn more?

Complete the form below and we'll be in touch soon.